Essential Masonry Tools & Supplies You Should Have

Imagine you’re halfway through a stone patio project when your trowel bends, your level gives false readings, and your mortar dries too fast. Frustrating, right? The right masonry tools and supplies can make or break your project—literally.

Whether you’re a professional mason or a weekend DIY warrior, quality tools help you achieve precise results, stay safe, and build structures that last. This ultimate guide walks you through the most essential masonry tools, their uses, and how to choose the best ones for your needs.

Measuring and Layout Tools

Every successful masonry project starts with precise measurements. These tools form the foundation of professional-quality work.

Tape Measure & Masonry Tape Measure

A masonry-specific tape measure offers crucial advantages for your next job. These specialized tools feature brick spacing scales along the bottom edge, allowing you to quickly calculate course heights without complex math. Professional masons prefer heavy-duty steel blades that resist kinking and feature positive locking mechanisms for hands-free operation.

Mason’s Level (Spirit Level)

Mason’s levels, typically four feet long or longer, provide the accuracy needed for professional results. Unlike standard construction levels, these tools withstand harsh masonry conditions while maintaining calibration. Magnetic levels offer particular value when working with metal reinforcement, keeping your hands free while you adjust materials.

Plumb Bob and Plumb Rule

Vertical alignment is critical for structural integrity. A plumb bob consists of a precisely weighted point suspended from a string, creating a perfect vertical reference line. Professional-grade plumb bobs use brass or steel construction for consistent weight distribution and weather resistance.

Mason’s Square (Setting Out Square)

This L-shaped steel tool ensures perfect 90-degree angles at corners. Quality squares maintain their accuracy over time, unlike cheaper versions that fall out of square after repeated use.

Cutting and Shaping Tools

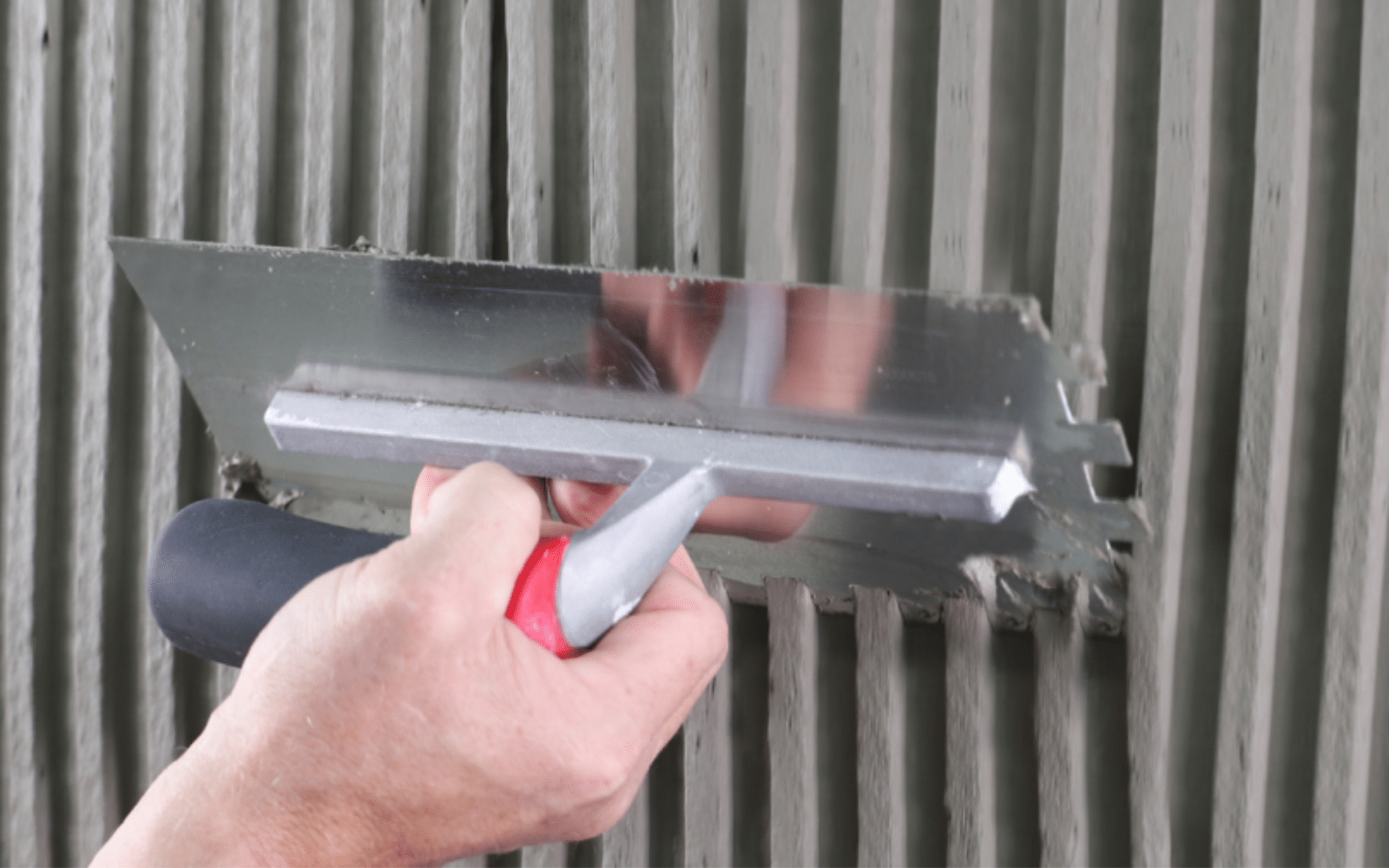

Trowels: The Mason’s Primary Tool

The mason’s trowel is indispensable for applying mortar evenly and efficiently. Professional trowels feature heavy-duty stainless steel blades with comfortable, ergonomic handles designed for extended use. Different trowel types serve specific purposes:

- Mason’s Trowel: This is the main tool used for spreading and shaping mortar on large surfaces.

- Pointing Trowel: Perfect for filling in joints and working in tight or detailed spaces.

- Corner Trowel: Used to create clean, sharp angles on inside and outside corners.

- Margin Trowel: Ideal for applying mortar in small areas or tight spots where larger trowels won’t fit.

Brick Hammer (Mason’s Hammer)

This specialized hammer features one flat face and one chisel edge, designed specifically for cutting and shaping brick. The dual design allows for both rough breaking and precision trimming, making it essential for any brick masonry project.

Chisels for Precision Work

Different chisel types serve specific masonry needs:

- Cold Chisel: Used for cutting through stone, brick, and other hard materials.

- Drafting Chisel: Helps create clean, straight lines along the edges of masonry work.

- Tooth Chisel: Ideal for surface dressing and adding texture to stone.

- Blocking Chisel: Designed for precision trimming and shaping in tight or detailed areas.

Power Saws for Heavy-Duty Cutting

Masonry saws equipped with diamond blades cut through dense materials efficiently. These tools range from hand-held models for small projects to walk-behind units for commercial work. Water cooling systems prevent blade overheating and reduce dust.

Material Handling and Mixing Tools

Mortar Pan

A quality mortar pan is essential for mixing and transporting mortar on the job site. Professional-grade pans use rubber or heavy-duty plastic construction for easy cleaning and durability. The wide, shallow design keeps mortar workable longer and allows easy access.

Concrete Mixer

For larger projects, a concrete mixer ensures consistent, high-quality mixes. Electric models work well for most residential projects, while gas-powered units provide portability for remote job sites.

Cart

A cart is also invaluable for transporting masonry materials and tools efficiently around the job site. Carts come in various configurations, allowing workers to move heavy loads with ease and improve workflow.

Wire Brush and Masonry Brush

These tools clean excess mortar and debris, giving finished work a polished appearance. Stiff-bristled brushes effectively remove loose mortar from joints without damaging surrounding materials.

Specialized Tools by Masonry Type

Stone Masonry Tools

Stone work requires specialized tools for shaping and dressing:

- Spalling Hammer: A heavy-duty hammer used for breaking and shaping rough stone.

- Point and Punch: Used for the initial rough shaping of hard stones during dressing.

- Claw Tool: Helps texture and smooth stone surfaces for a more finished look.

- Wedge and Feathers: A traditional method for splitting stone with precision using controlled pressure.

Brick Masonry Tools

Brickwork uses specific tools for precision:

- Lump Hammer and Bolster: Used together for accurate cutting and shaping of bricks.

- Double-end Comb Hammer: Ideal for removing excess material and cleaning up rough surfaces.

- Brickwork Gauge Rod: Helps maintain consistent brick course levels throughout a project.

Safety Equipment and Best Practices

Safety should never be compromised on any masonry project. Essential protective equipment includes:

Personal Protective Equipment (PPE)

- Safety goggles for eye protection

- Work gloves designed for masonry materials

- Steel-toe boots for foot protection

- Dust masks for respiratory safety

- Hard hats for overhead protection

Job Site Safety

Maintain a clean, organized workspace to prevent accidents and improve efficiency. Store tools in designated areas, secure loose cords, and keep walkways clear of debris to reduce tripping hazards. When lifting heavy materials, use proper body mechanics or lifting aids to protect your back and avoid strain. Always wear appropriate safety gear like gloves, goggles, and steel-toe boots to stay protected on the job.

Tool Quality and Selection Guide

Professional vs DIY Considerations

Professional-grade tools offer superior durability and performance but come at higher prices. For occasional DIY projects, mid-range tools provide good value. However, investing in quality pays dividends for frequent use or professional work.

Quality Indicators

Look for these features when selecting masonry tools:

- Construction Materials: High-carbon steel blades, comfortable grip materials

- Ergonomic Design: Tools are designed to reduce fatigue during extended use

- Warranty Support: Reputable manufacturers stand behind their products

- Professional Recommendations: Tools endorsed by working masons

Tool Maintenance and Care

Proper maintenance extends the life of your masonry tools and keeps them working safely and efficiently. After each use, clean off mortar and debris, dry metal surfaces to prevent rust, and store tools in a dry, organized space.

Regularly sharpen cutting edges, lubricate power tool parts, and inspect for wear or damage. Replace any worn or compromised tools before they become a safety risk. A little upkeep goes a long way in protecting your investment and ensuring reliable performance.

Conclusion

Having the right masonry tools and supplies is essential for building with confidence, whether you’re crafting a stone wall, laying brick, or tackling a concrete project. From measuring and cutting to mixing and finishing, each tool plays a crucial role in ensuring your work is safe, accurate, and built to last. By investing in quality equipment and maintaining it properly, you’ll not only improve your results but also make every project more efficient and enjoyable.

At Old Station Outdoor and Landscape Supply, we carry a wide selection of professional-grade masonry tools and supplies trusted by contractors and homeowners alike in Norton, MA. Whether you’re starting your first DIY project or gearing up for your next job, our knowledgeable team is here to help you choose the right tools for the task. Visit us today or contact us to get everything you need to build with strength, precision, and lasting quality.

FAQs

What are masonry tools and equipment?

Masonry tools and equipment are specialized instruments used for cutting, shaping, measuring, and installing brick, stone, concrete, and other masonry materials. These include hand tools like trowels, hammers, and chisels, as well as power equipment such as concrete mixers and masonry saws that you can shop for at professional supply stores.

What masonry materials and tools will you use?

Essential masonry materials include bricks, stones, mortar, and concrete, while key tools encompass trowels, levels, hammers, chisels, measuring tapes, and safety equipment. The specific selection depends on your project type, and you’ll need to sort through options based on whether you’re doing stone work or brick projects.

How do you take care of masonry tools?

Clean tools thoroughly after each use to remove mortar and debris, then dry and store them in organized, moisture-free locations. Regular maintenance includes sharpening cutting edges, lubricating moving parts on power tools, and choosing tools with ergonomic designs for comfort during extended use.

How can you prevent the dangers of masonry tools?

Always wear proper safety equipment, including goggles, gloves, steel-toe boots, and dust masks when using masonry tools. Maintain a clean, organized workspace, inspect tools before use for damage, and follow manufacturer safety guidelines for all power equipment.